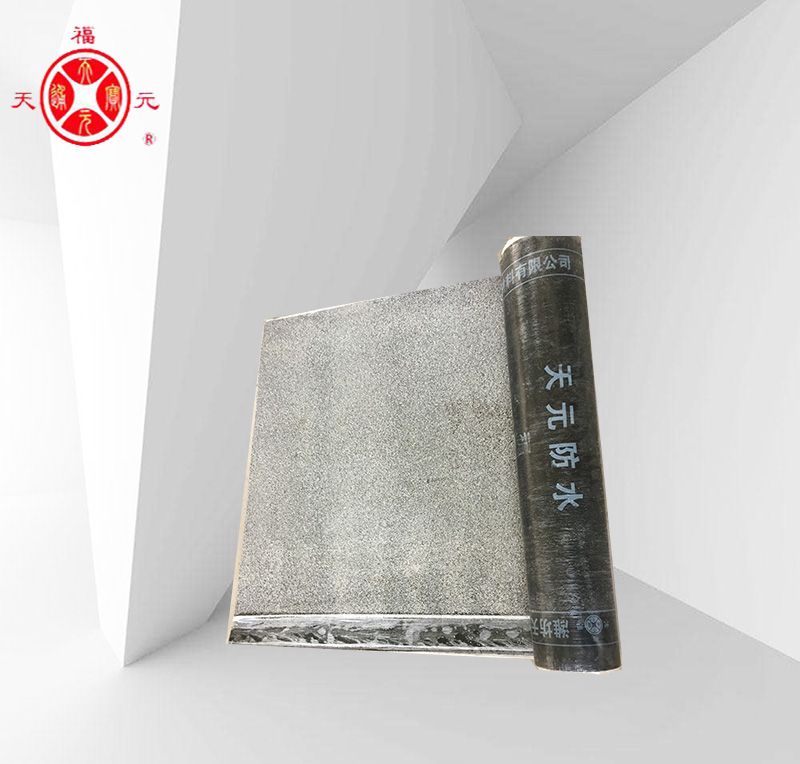

polyurethane waterproof coating-pg电子模拟器入口

product profile:

waterborne 951 polyurethane waterproof coatings and oily 911 polyurethane waterproof coatings

951 waterproofing coating is made of vae and acrylic copolymer emulsion as the base material, modified by specific process. it has the characteristics of high elasticity of organic materials and good durability of inorganic materials, and its comprehensive performance reaches the advanced level of similar products in china.

product specification:

national standard/enterprise standard

use site:

kitchen, bathroom, balcony

step one:

in the treatment of grass-roots, the grass-roots should be firm, flat, free of impurities, fully dry, and the yin-yang angle should be circular arc, with the diameter of yin-yang angle greater than 50 mm and the diameter of yang-angle greater than 10 mm.

step two:

ingredients and dosage: according to construction dosage, single component open cover mixing can be used evenly. reference dosage: 1 mm thick film dosage is about 1.3-1.5 kg/m2.

step three:

large-area waterproof construction: uniform coating with rubber or plastic scrapers, requiring uniform thickness, generally 1.5mm-2mm, should be divided into 3-4 times of painting, the next painting should be solidified after the previous painting, and be painted in a vertical direction, generally as a separate film, the floor of underground engineering should be coated with a layer of matrix reinforcement material.

step four:

coating film thickness: underground engineering is 1.2mm-2.0mm, generally 1.5mm, toilet bathroom is not less than 1.5mm. when exposed roof engineering adopts multi-channel waterproofing, the thickness of each channel is not less than 1.2mm. when waterproofing grade is iii roof, waterproofing thickness is not less than 2mm. when adding matrix reinforcement material between layers, the thickness of the layer below the matrix. no less than 1.0mm and the top layer is no less than 0.5mm.

step five:

finishing layer construction: scatter clean sand on the surface before brushing the last time the paint has not solidified.

step six:

protective layer: the surface of the waterproof coating should be insulated according to the design requirements.

| prev:delivery site | next:delivery site |